The new SmartCut tiller from PistenBully

Greater efficiency. Higher quality. As standard.

At the end of the day, guests see only one thing: a perfect slope. For those responsible for the slopes, however, it's the journey that counts—efficiency, cost-effectiveness, and technology must be just as important as the result. This is exactly where the new SmartCut groomer from Kässbohrer comes in. After all, the groomer plays a key role in determining the final result.

Listen, test, think ahead: development based on practical experience

The starting point for this development was not the drawing board, but practical experience. Over several seasons, the pre-development team at Kässbohrer listened intensively: feedback from customers, experience from daily use, and input from sales and service were consistently brought together. Through close collaboration, different approaches, state-of-the-art development methods, and numerous test runs, the vision of a snow groomer that optimally meets the requirements of modern slope preparation emerged step by step. The result is a ready-for-market production that will be installed as standard in all vehicles from the 2026/27 winter season.

Innovation that sets standards

With the introduction of this standard feature, Kässbohrer is sending a clear signal. State-of-the-art tilling technology is becoming standard and provides another decisive argument in favor of the PistenBully. Operators automatically benefit from greater precision, efficiency, and durability—advantages that pay off measurably in daily use.

Visibly better: finer tilled material for perfect cord structures

The focus is on significantly improved slope quality. The new SmartCut tiller with an optimized overall system consisting of a cutter bar and finisher comb produces particularly fine-milled snow that is evenly distributed and enables a clean, stable finish. The result is more homogeneous and resilient slopes – visible to every guest and noticeable to every skier.

Maximum efficiency with minimum power requirement

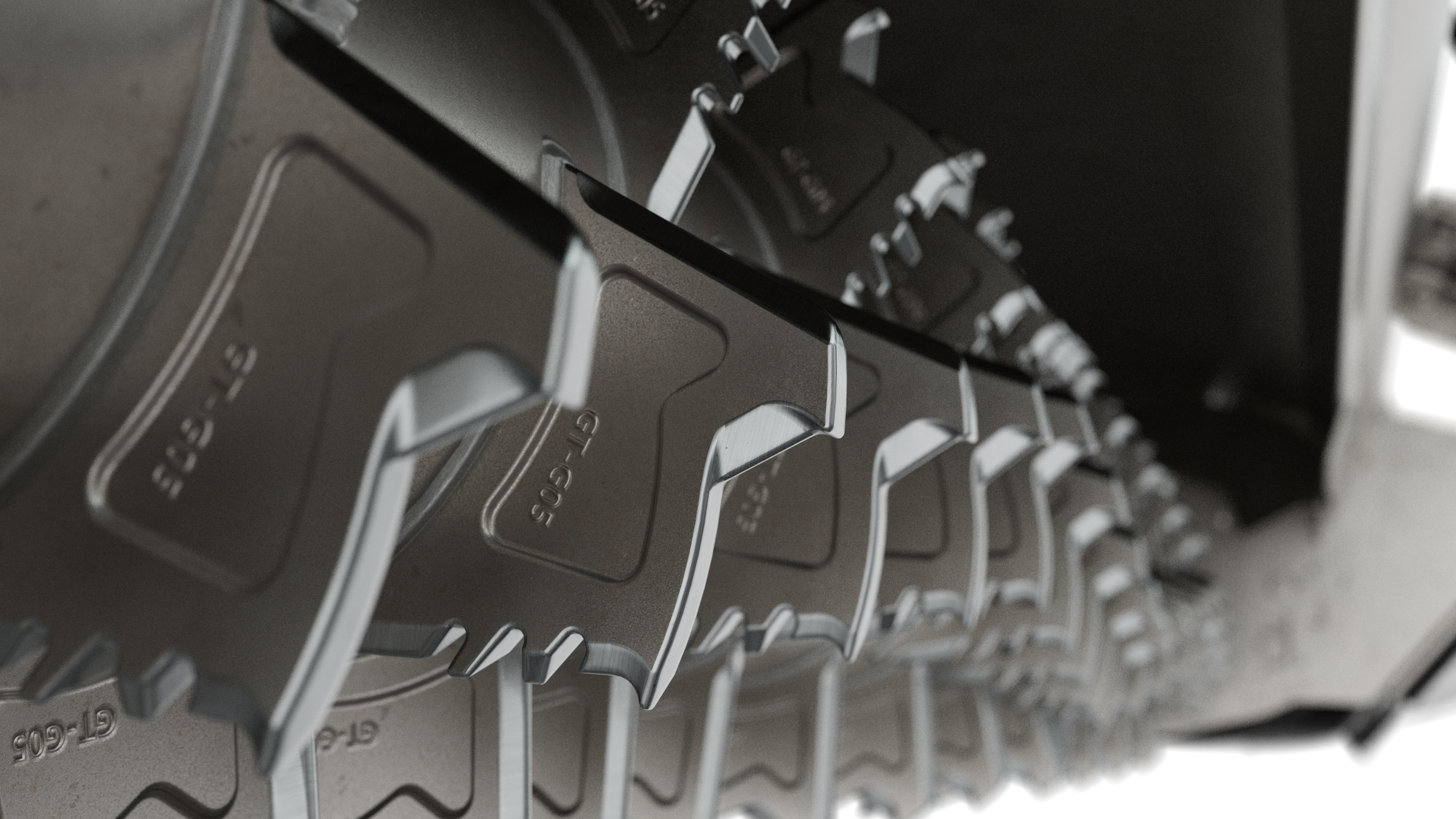

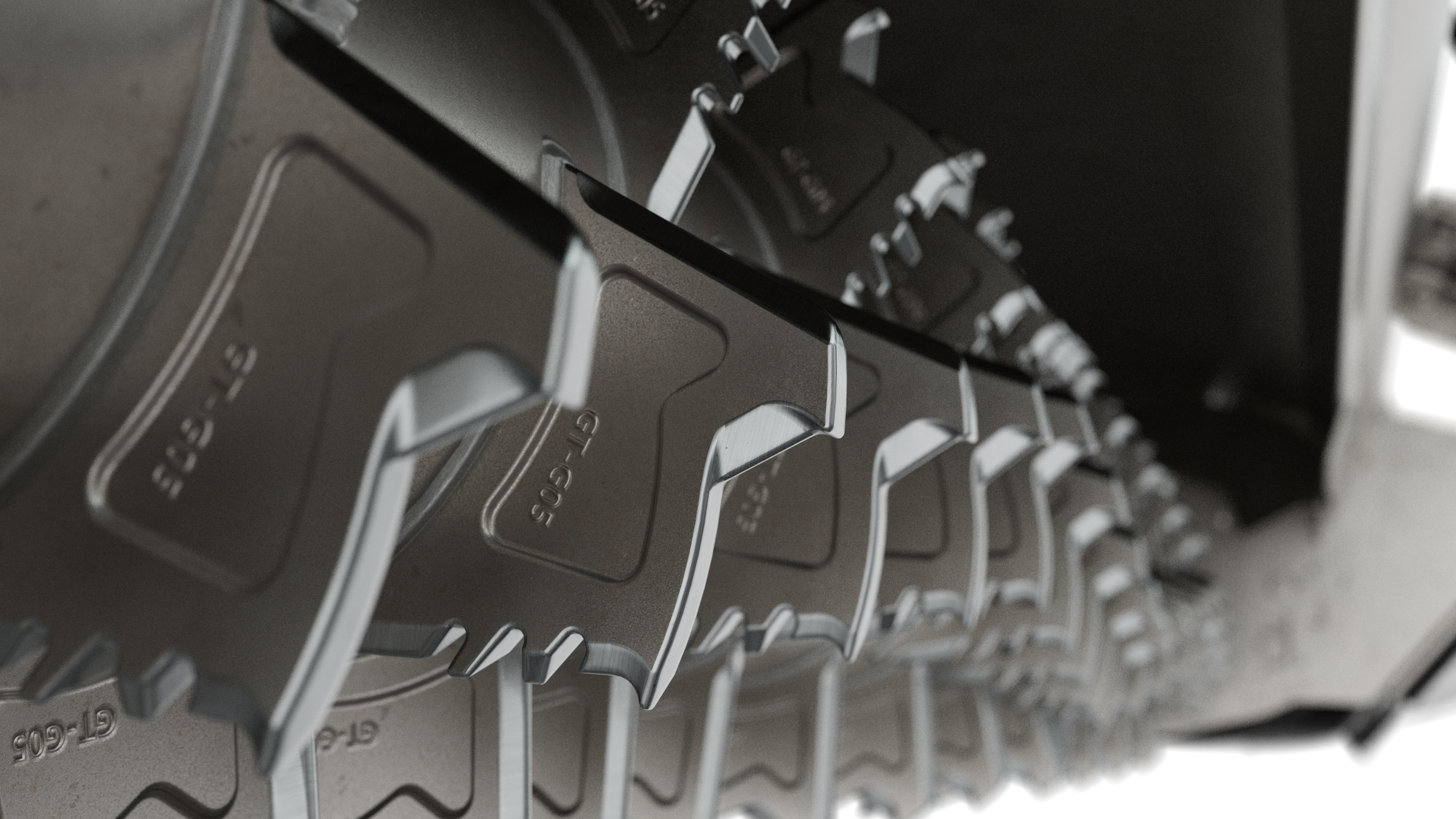

A newly developed cutter bar tooth with optimized geometry and two sharp cutting edges ensures particularly efficient grooming of the slope. The lower resistance reduces the power requirement. Even on the first pass, ice and hard snow are effectively broken up, eliminating the need for double passes and increasing the overall efficiency of slope maintenance.

At the same time, SmartCut technology allows you to work with reduced tilling depth and lower contact pressure – without compromising slope quality. To exploit the full savings potential, the tiller must be adjusted to suit the situation.

Gentle on material and slopes

The new tiller also sets new standards in terms of technology. The optimized geometry of the cutter bar ensures smooth running, reduces mechanical stress, and minimizes wear. The technology is noticeably relieved – sustainable preparation in the best sense of the word.

Clean finish – even in curves

The three-stage finisher comb ensures optimal distribution of the groomed snow and maximum directional stability, even in curves. Even in challenging terrain, the result is uniform without smearing. For the driver, this means more comfort, less contact pressure, and the ability to work at higher speeds without compromising on quality.

The result counts. And it's impressive.

More even, more stable slopes with a perfect corduroy structure make the new SmartCut tiller a key component of modern slope preparation. Available as standard in the PistenBully from the coming winter season – developed from practical experience, for practical use – with the aim of getting the best out of every slope.

Dr. Christian Oberwinkler, Chief Technology Officer (CTO):

"For us, the new SmartCut groomer is the logical next step in slope preparation. It combines visibly better slope appearance with greater efficiency and noticeable relief for the technology. Thanks to the optimized milling geometry and SmartCut technology, we can cut snow and ice more precisely, require less power, and produce finer milled material. More uniform, stable slopes with reduced wear and lower energy consumption – the fact that we will be using this technology as standard from the coming winter season underlines our commitment to making innovation the norm. We were only able to achieve this result through the consistent involvement of our customers throughout the entire development period, combined with the latest simulation methods."