for the bully

Here you will find some service tips and tricks for PistenBully. From now on, KÄSSBOHRER's technical experts will be writing regularly about maintenance

and service topics that can be used to operate the snow groomers more efficiently, trouble-free and gently.

#1: Shortage the winch rope

To do this, clamp the winch cable in a vice, grasp the loose end with a suitable turning tool, and heat the winch cable in the range ≈ 100 mm / ≈ 3.94 in with a welding torch. When the winch cable begins to glow, you slowly turn it counterclockwise three to four turns using the tool. You are virtually twisting the winch cable shut! The winch cable finally breaks in the glowing area. It is important that you increase the force slowly and evenly when turning the winch cable in order to achieve as smooth a break as possible. Finally, allow the winch cable to cool completely and then remove the burr with a suitable grinder.

#2: Battery check

To ensure proper functioning of the battery (whether maintenance-free or not), the battery switch should be disconnected to avoid creep and discharge currents. The open-circuit voltage should be checked after a standstill period of no more than six months. This must not fall below 12.4 volts on the single battery, otherwise it must be recharged. Use a regulated charger (10% battery power), but do not use fast charging functions. Rather, the charging time should be several hours to avoid sulfate formation with damage, heat and outgassing. After charging and cooling the battery, the resting voltage should be about 12.7 volts.

For batteries that are not marked as maintenance-free by the type plate and have screwed/plugged caps or maintenance openings on the top, the following applies: Additionally check the liquid level and supplement it with distilled water to MAX.

In general, make sure that the battery is stored in a dry and cool place at 0°C to +25°C. Always follow the maintenance instructions. There is a risk of burns due to liquid, short circuit due to chemical reaction or explosion due to gas!

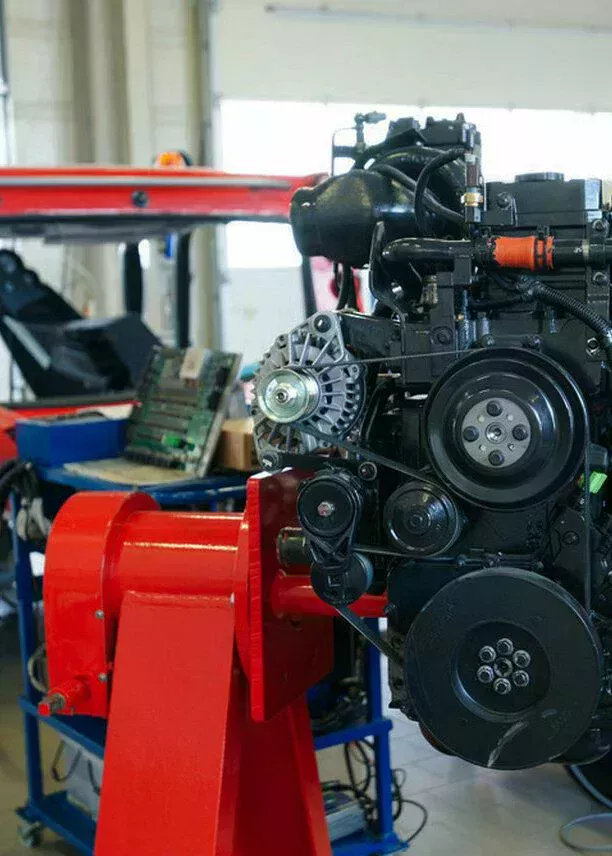

#3: Cummins engine

As you know, the new PistenBully 600 EU 5 has a Cummins X12 engine, which has the following advantages over its predecessor:

- Additional torque

- The best power-to-weight ratio

- Lower fuel consumption

We recommend to hold the engine speed at 1,300 revolutions per minute. At this engine speed, the highest torque with the lowest fuel consumption and optimum hydraulic performance can be achieved.

#4: iTerminal

The PistenBully iTerminal with its 10.4" color touch display allows the operator a quick overview of all the information and parameters needed for his work.

On the home screen, all important engine data is displayed in the digital cockpit. Menu buttons take the operator to the relevant submenus, vehicle information and vehicle settings. The cameras are also displayed via the iTerminal.

To make the operation as intuitive and simple as possible for the driver, the iTerminal offers the option of gesture control, as usual on a smartphone. For example, displays can be easily switched by swiping across the display.

To quickly get back to the home screen, you only have to perform a roof shape gesture ^ on the screen. If you want to go back to the previous page, you can simply use the gesture of an L shape. If you do not want to use the gesture control, you can of course also navigate via the conventional buttons.

#5: Winch

Namely, it's about calibrating the remaining rope length. After a rope change of the 4.5 and 4.6 ton drive drum winch, you should carry out various calibrations via the iTerminal. This includes the calibration of the layers and windings on the reel. You need the exact number of layers and windings to correctly calculate the available remaining rope length. The information also allows you to correctly detect rope winding errors.

To avoid having to count the layers and windings on the reel all the time during rope spooling, we recommend the following tip: Spool up the new winch rope about five windings so that the rope is firmly seated on the reel. Now briefly interrupt the spooling process. Enter the current number of layers and windings on the calibration page in the iTerminal (e.g.: zero layers, five windings) and confirm your entry.

Now the winding can be continued. This allows you to concentrate fully on winding without being distracted by counting. For control purposes we recommend - after the end of the process - to recount and compare the number of windings again.

#6: Drive wheels

To set the PistenBully in motion with its tracks, large sprocket wheels are required that are bolted onto the planetary gearbox at the rear of the vehicle. These drive wheels are also called turas.

To ensure that the PistenBully gets all its power, the turas are subjected to greater stress, especially when pushing and driving uphill. In addition, the vehicle travels forward most of the time, which often results in one-sided wear on the drive wheels.

To counteract this and extend the service life, we recommend changing the drive wheels from right to left at the appropriate time. This means that the less worn side is available for the more demanding work. By changing the turas, they can be better utilized and must be replaced later. This conserves resources and reduces maintenance costs.

#7: Digital maintain

Today we show you how easy it is to get started with the digital maintenance of your PistenBully. SnowSat Maintain Basic is the name of the free maintenance software.

In SnowSat Maintain Basic you can add your PistenBully including additional equipment and thus keep an eye on your fleet - with newer vehicles, you can even see the current operating hours. We keep all technical documents up to date for you on an equipment-specific basis. You can also plan, perform and document maintenance at an early stage. So the first steps in digitalized maintenance are quickly taken!

To register, please contact your service partner. They will create an account for you and support you in setting up your account. And when you have become really digital, you can easily upgrade the software to SnowSat Maintain Professional, where all assets (equipment and facilities) can be managed!

#8: Windshield wiper

The clear view on the mountain: You can control the windshield wipers on the PistenBully 600 (Generation 826) either via the control panel or via the steering column lever on the left side of the steering wheel.

To avoid damage to the functional mechanism of the windshield wipers, we advise you not to use the control on the steering wheel, but the buttons on the panel. You wonder why? If the wiper control is not set to 0 at the end of the shift, the wipers will automatically restart at the next engine start. If there is heavy, wet snow or even ice on the windshield at this time, it can cause the wipers to wear out faster.

#9: Refuel correctly

Refueling vehicles is not difficult. Nevertheless, there is an important tip for the PistenBully: Always top up your vehicle's fuel tanks after you have finished driving. This prevents condensation from accumulating in the fuel tanks!

To explain: The fuel and the tanks heat up due to warm returning fuel and the waste heat of the components. If the vehicle is parked with empty tanks, the heated air in the tanks cools down and the moisture bound in the air condenses on the tank walls. This moisture accumulates at the bottom of the tanks and, in the worst case, is sucked in and freezes in the lines during a cold start. It is then no longer possible to start the vehicle. If the tanks are full, there is no room for air and the condensation effect is prevented.

#10: Tips for oversummering

A checklist to help a PistenBully get through the summer well:

- Wash vehicle, tracks and attachments

- Perform pending maintenance / summer overhaul

- Dismantle chains, cover spike tips and wind up, store upright

- Jack up vehicle in order to relieve the suspension of the chassis

- If necessary, cover the intake and exhaust openings

- Protect vehicle, tracks and attachments from sunlight

- Fill fuel tank completely to avoid condensation water

- Drain water from water separator

- Fill DEF tank

- Check hydraulic oil and fill up

- Lubricate

- Let oil out of high-pressure hoses of the dismantled auxiliary equipment in order to relax them

- Disconnect the battery and connect it to the trickle charger

#11: Dream job Pistenbully operator

The shortage of skilled workers is currently hitting hard, and ski resorts are urgently looking for PistenBully operators. But how do you actually become a professional operator?

The ProAcademy of the PistenBully manufacturer KÄSSBOHRER offers beginner training courses for slope grooming: Important, manufacturer-independent basic knowledge for everyone – from the technical functioning of a snow groomer to its correct operation and basic knowledge of slope preparation. But also information on safety and necessary daily maintenance work are part of these courses. After passing the exam, the graduate receives a recognized ProAcademy certificate at the end of the theoretical operating training, in which the training contents are documented.

No less important, of course, is the practical operater training. Here, the newcomer learns the basic functions of a snow groomer and how to use it in practice. German-language beginner training courses in presence take place in October in southern Germany, Austria or South Tyrol.

If there is no service contract with a ski resort yet, interested parties can find some job offers on the job portal of KÄSSBOHRER.

#12: AdBlue and DEF fluid

AdBlue is a well-known brand name, as used by Mercedes, for example. The manufacturer of the PistenBully engines, Cummins, calls the liquid Diesel Exhaust Fluid – DEF for short.

Whether you call it DEF or AdBlue, both fluids reduce exhaust emissions in diesel engines. They are a mixture of 32.5 percent urea and 67.5 percent water.

DEF freezes at minus 11 °C / 12 °F – but can be thawed without loss of quality. However, the storage temperature should not exceed 30 °C / 86 °F. DEF has a shelf life of one year, provided the containers are tightly sealed. Be careful, because evaporation of the water content leads to a change in the mixing ratio of urea and water and can cause errors in use. In addition, DEF must not be exposed to direct sunlight.

#13: SnowSat Training

Efficient slope and snow management is becoming increasingly crucial to the success of a ski resort. Especially in the current times, resources are also more valuable than ever for ski resorts. Through the SnowSat trainings, PistenBully operators and slope managers can get the maximum out of the individual SnowSat solutions.

The SnowSat trainings are now offered under the ProAcademy umbrella. The aim is to prepare employees in the best possible way for efficient and resource-saving work in the ski area.

In the 2022/23 season, basic courses on SnowSat in the vehicle and in the office can be booked in the ProAcademy portal. In addition, ProAcademy provides advice and training on efficient snow management with SnowSat, on maintenance with SnowSat Maintain – and how to optimize and expand maintenance.

#14: Check The Battery

Proper care for batteries is important so that they function flawlessly (whether or not they are maintenance-free). If there is an extended downtime, the battery switch should be disconnected to prevent leakage current and discharge current. After a downtime of six months at the latest, check the open-circuit voltage. This must not fall below 12.4 volts at the individual battery, otherwise it has to be recharged. Use a regulated battery charger (10% battery rating), but do not use any rapid charging functions. Instead, the charging time should be several hours to avoid sulfur formation along with damage, heat and outgassing. After the battery has been charged and has cooled off, the open-circuit voltage should be at approximately 12.7 volts.

For batteries that are not labeled as maintenance-free on the type plate and have end covers or maintenance openings screwed/plugged in on top, the following applies: Additionally check the fluid level and add distilled water up to the MAX line.

In general, make sure you store the battery in a dry and cool area at a temperature from 0 °C to +25 °C. Always follow the maintenance instructions. There is a danger of chemical burns from liquid, a short circuit from a chemical reaction or an explosion from gas!

#15: Start the season in good shape

Think about the annual review of your PistenBully vehicles. The inspection and maintenance of snow groomers is an important topic—one that we would like to talk about with you.

This is why we are now making you this offer: Conclude a maintenance contract for your PistenBully with our Service department. As part of the summer promotion, we are offering a complete inspection of the vehicles with highly attractive terms. After the inspection, you will receive a maintenance report. The maintenance contract includes at least one annual inspection by qualified service personnel in accordance with the PistenBully maintenance guidelines. Customers can order the required service materials cost-effectively from PistenBully service technicians.

Curious? Then get in touch with your Service contact person

#16: 3D target profiles for more efficiency and quality

Particularly at the on/off points of transport equipment, their turnstiles and drag lift lines, it is always important to have an exact snow depth. But also when a park or cross run is being constructed, the setup has to be the same every day or even every year.

You can receive support for this from the SnowSat snow depth measuring system with what is called the DSM (digital surface model). The DSM (= target profile) can either be created on a computer or be generated from measured snow depth data. Then it is provided in the vehicles. If necessary, the DSM can be selected in the SnowSat system. Then the SnowSat system shows you not only the measured snow depth under the vehicle, but also the difference from the target profile. As a result, the operators each know where they have to build up snow or remove it.

#17: Keep SnowSat terrain

models up to date

If changes were made to the terrain over the summer, the snow depth measurements will differ in these areas because the original terrain model no longer corresponds to the real situation on-site.

This is important, however, for ensuring snow depth measurement that is consistent and highly accurate. In the event of changes, therefore, a new or at least partially (at the modified locations) updated terrain model should be created. Especially in autumn, you have one last chance again, before the first snowfall, to create a terrain model by means of drone surveying flights so that you can get an accurate measurement in winter. If the surveying flights don't happen until snow has already fallen, the snow measurements displayed later will no longer correspond with each other and the slopes will no longer be able to be groomed optimally!

#18: The easy way to the right spare part

A vehicle as complex as the PistenBully also requires a complex range of spare parts. Different model series, numerous variants, over 15 years of stock: it's easy to lose track even in the most sophisticated web store! To support employees, the ProAcademy is now offering a free training course.

In three units, this course teaches the basics of using the KÄSSBOHRER webshop. Using examples, illustrated charts and simple explanatory videos, participants are given an overview of the logical procedure for finding the right spare part.

After an introduction (registration, user data, ET actions, etc.), the training intuitively leads to the ET catalog and provides important answers on topics such as navigation in the catalog: Structure of vehicle, engine or additional equipment or creating a vehicle using the chassis number.

The webshop itself provides tips on how to create a specific fleet - as a basis for a simple ordering process or the use of order templates.

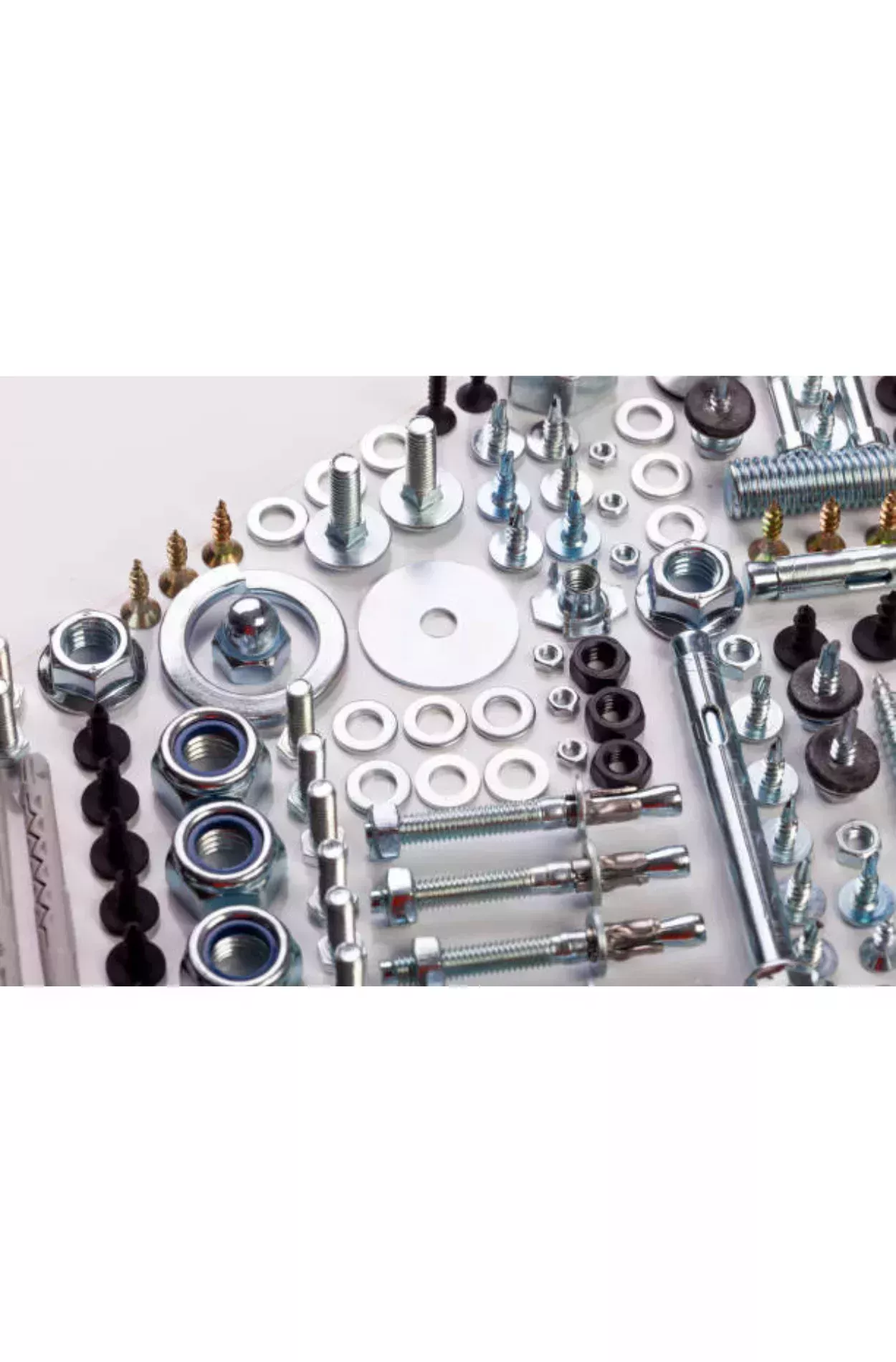

#19: Find the right parts

Standard and DIN parts, i.e. mainly small parts such as screws, grease nipples or seals, are immeasurable in their variety. All of these parts, which are standardized in the machine industry, will in future be displayed with exact designations and dimensions in the KÄSSBOHRER spare parts catalog.

This facilitates the simple and correct definition of the required spare part and thus increases the security and reliability of a correct parts order. If necessary, customers can also easily access existing stock parts and rectify the machine failure even faster. ProAcademy is now also offering free training to support the webshop. This saves costs, time and nerves!

#20: Short videos about Snowsat ix

There is now a YouTube playlist with helpful tips on operating SnowSat.

The video series deals with seasonal features and reflects the experiences of customers who already work with SnowSat iX.

After all, it's good to know how users can easily create individual screen layouts and split screens - for example, for the simultaneous display of snow depths and tracks. Or how users can save their favorite views and personal settings in their user profile and take them with them on every snow groomer.

The short video sequences also cover how to easily switch between light and dark mode on the screen for an optimal display, how drivers identify snow reserves and use the snow groomer assistant. Other content includes working with cost centers, to-dos and geopoints. So, watch the videos, get in and drive off!

#21: Replenish operating materials

The end of the season is in sight and it's time to check and maintain the PistenBully. However, please also ensure that you use the correct operating fluids when carrying out daily checks on the PistenBully!

Do not rely on the color of the operating fluids and do not mix them. For example, there are two different coolants for the vehicle engine with the same pink color, but with completely different properties. Therefore, observe the information in your maintenance instructions. Do not mix cooling lubricants or oils with different specifications.

Incidentally, you can conveniently obtain all operating materials for your vehicle from the Kässbohrer Geländefahrzeug AG webshop.

#22: Ergonomically configuring the joystick and armrest

In a PistenBully, you have numerous options for configuring the workstation ergonomically. The position of the joystick and armrest are an important part of this.

First, set the distance between your hand and the joystick. To do so, pull up the top lever of the two on the front side of the seat and slide your seat until your right elbow is resting on the armrest at about a 90-degree angle when you take hold of the joystick. To adjust the angle of the joystick, press and hold the button on the left side panel of the armrest and swing the joystick into the desired position. Then fold up the armrest pad and use the two handwheels in the armrest compartment to adjust the height and angle of the armrest.

Now your entire forearm should rest comfortably on the armrest when you take hold of the joystick.

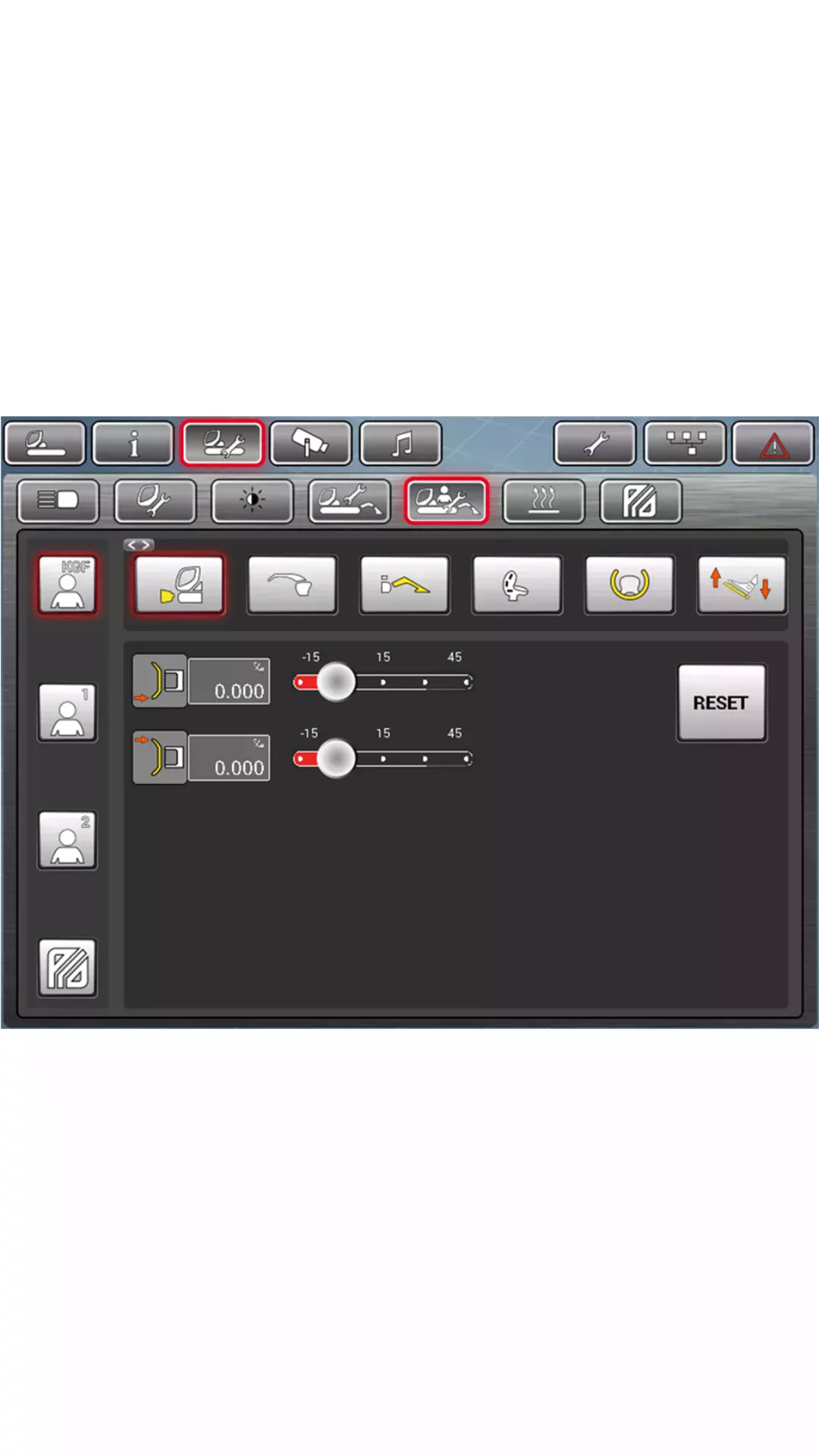

#23: Setting up your operator profile

Does the steering of your PistenBully respond too aggressively for your liking? Or does the implement carrier steer to the side too slowly? Then it's time for you to customize your operator profile and tailor it to your individual needs!

To do this, navigate to the user-specific iTerminal settings for the operator (see screenshot).

In this settings menu, you can configure up to three operator profiles. Select an operator profile and adjust the settings or characteristics of the following components:

- All way blade

- Capstan winch

- Implement carrier / snow tiller

- Joystick

- Steering wheel / stick steering

- Throttle pedal

Tip: In the operator's manual for your PistenBully, you will find detailed descriptions of all the individual adjustment options.

Are there other challenges we can help you with? Then send an email to ideen@pistenbully.com.